Artisan Hiroyuki Kambayashi

Second-generation CEO/Artisan of Katsumi Shoten Co., Ltd. Hiroyuki Kambayashi Born in Kami-Katsura, Kyoto, in 1971. Raised helping with dyeing tasks at the family workshop from an early age, Hiroyuki began formal apprenticeship training at 15. After honing his skills for several years, he moved to Tokyo at age 20, where he worked for an apparel manufacturer for three years. Returning to Kyoto, he deepened his expertise in Roketsuzome, gaining numerous fans both domestically and internationally. Hiroyuki expanded the workshop's portfolio by integrating Roketsuzome techniques into contemporary fashion and modern lifestyle textiles, establishing his unique style. Under his leadership, SHOBIEN expanded its market reach to seven countries, earning high acclaim globally. Currently, Hiroyuki is broadening the company's horizons further by developing wallpaper dyed using Roketsuzome methods. He diligently carries forward the spirit of craftsmanship and management inherited from Katsumi, continually refining his skills to preserve and pass on the beauty of Roketsuzome to future generations.

About Company

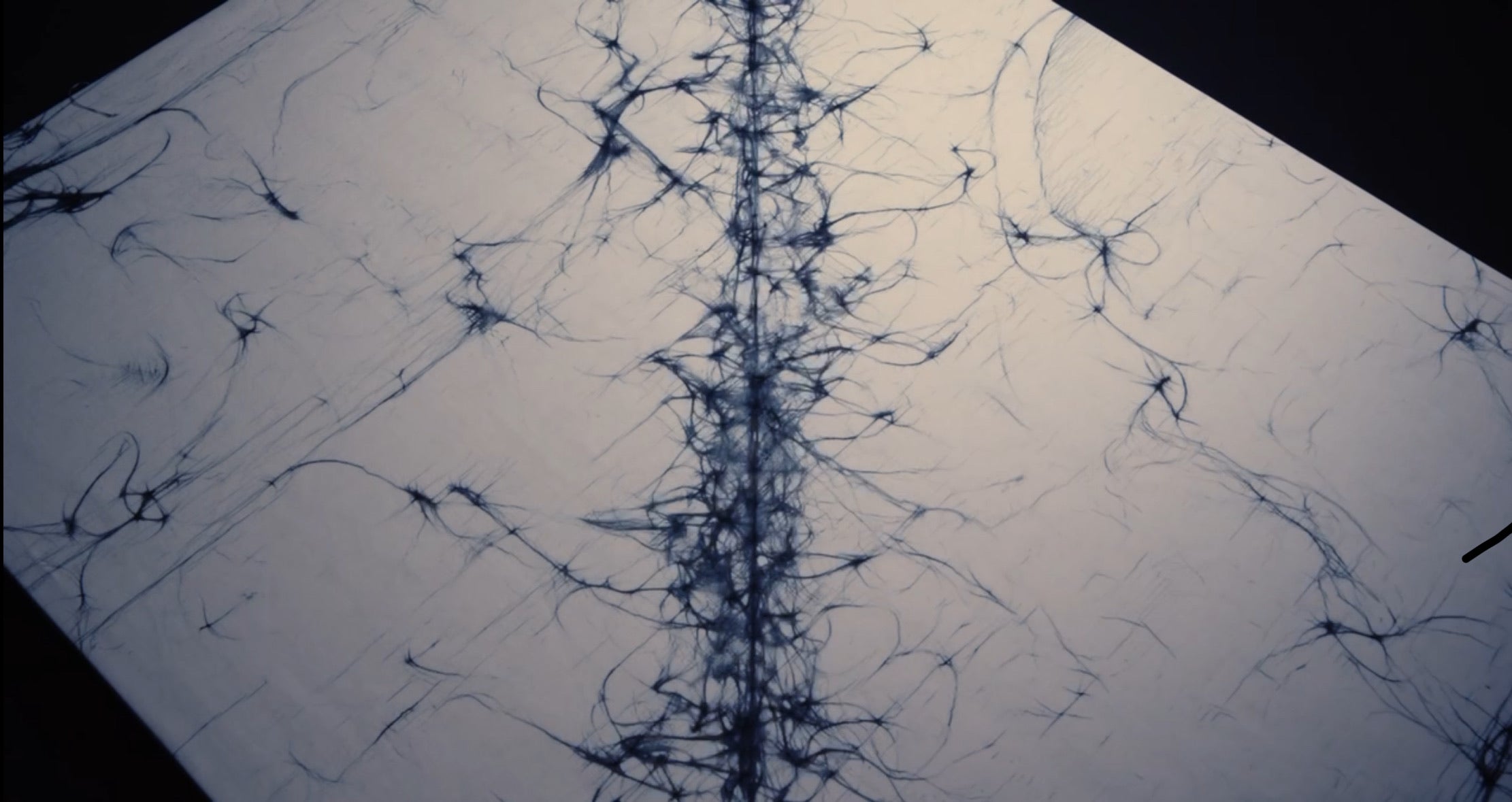

2nd generation artisan/ceo Hiroyuki Kambayashi Our workshop is located in Kamikasa, Kyoto, passing on the tradition of roketsuzome. A Brief Family History Founder, Katsumi Kambayashi founded roketsuzome studio in Kamikatsura, Kyoto, where our family has carried on the technique for over sixty years. (Left: Katsumi Kambayashi, founder of Shobien kyoto) The Craft Heritage of Kamikasa Hata clan—immigrants from the Asian continent—dug an irrigation canal from Arashiyama. Their engineering turned the area into an aristocratic estate where agriculture, dyeing, and sake brewing thrived. Rōketsuzome itself also arrived from the continent in that same period, becoming one of the region’s signature arts. What Makes Rōketsuzome Unique Wax as a Resist Wax melts at roughly 140-160°C. When we brush the hot wax into fabric, it soaks in and quickly solidifies, blocking the dye wherever it sits. Crackle Patterns By gently squeezing or bending the cloth, we create tiny cracks in the wax. Dye seeps through those fissures, producing delicate lightning-like lines called hibiwari (“crackles”) or rō-fubuki (“wax snow”). Every piece develops its own, never-to-be-repeated pattern of soft curves and veining—inimitable beauty born of controlled chance. Looking to the Next Century Even after six decades, our workshop is still considered “young” in Kyoto’s long timeline of textile history. Today only a handful of studios continue rōketsuzome, and ours is the sole atelier in Kyoto capable of dyeing extra-wide fabrics. We think constantly about how to preserve the craft and communicate its beauty a hundred years from now—so that the quiet magic of wax, dye, and hand-formed crackle will endure for generations to come. Mission Inheriting the Tradition of Roketsuzome, Co-creating the Future Roketsuzome has taught us the beauty inherent in imperfection. The hallmark of Roketsuzome is its distinctive crackle patterns. This traditional dyeing technique has been handed down since the Tenpyō period. Historically, pieces exhibiting crackle patterns were considered flawed, and only products without these cracks were accepted as perfect Roketsuzome. With the advance of mechanized dyeing processes today, achieving flawless products is no longer a challenge. Yet, this begs the question: What truly defines Roketsuzome? We embrace the imperfect beauty embodied by crackle patterns as the very essence of Roketsuzome. By expressing human warmth through these patterns, we aim to pass this unique aesthetic to future generations, collaboratively shaping the beauty of tomorrow. Vision Returning to Humanistic Craft Rediscovering the beauty in imperfection. People are moved and deeply touched by the human qualities reflected in handcrafted works. The unique charm arises precisely because these pieces are made by human hands. Patterns born from unexpected moments, the spontaneous beauty emerging naturally from manual creation, and the values cultivated through coexistence with nature. In a highly mechanized world, humanity is gradually lost. A society of perfection, where there is no space for personal touch, where AI surpasses human involvement. By interacting with objects imbued with humanity, even subtly, our hearts are moved, and our lives enriched. We are dedicated to continuously creating works that bring human warmth and color to people's hearts.

Process of Making Roketsuzome Noren

Step 1 Pattern Alignment & Sketching The design is carefully sketched onto fabric using a specialized "Aobana" pen at actual scale. Even a slight misalignment between the design and fabric can lead to significant distortion in the final dyed pattern. Therefore, the design sketch is meticulously aligned, pinned, and taped to the fabric to prevent any movement. This step, although seemingly simple, demands great care and precision, as even minor misalignments have major impacts on the final product. Step 2 Wax Application Following the initial sketch, wax heated between 140°C and 160°C (temperature varies with ambient conditions) is applied precisely onto the fabric using specialized brushes. Wax serves as a resist, preventing dye absorption during the subsequent dyeing step, thus preserving the pattern. Because wax cools rapidly, becoming difficult to apply smoothly, brushes must be continuously dipped in hot wax to maintain optimal temperature. Standard brushes cannot withstand these high temperatures; therefore, specialized Roketsuzome brushes are used. Step 3 Hand Dyeing The waxed fabric is submerged in dye solution for approximately 20 minutes. Kyoto's groundwater, drawn from wells, maintains a consistent temperature year-round, providing ideal dyeing conditions. Since wax has a melting point around 60°C, it solidifies upon immersion in the 18°C dye bath. The solidified wax is then cracked manually, allowing dye to seep into these fissures, creating the distinctive Roketsuzome crackle patterns. Each handcrafted dyeing yields a unique pattern, ensuring every piece is one-of-a-kind. Step 4 Wax Removal After drying the dyed fabric for about one day, it is submerged in boiling water to remove the wax. The wax floats to the surface, separating naturally from water, allowing it to be collected and reused. This recyclability makes Roketsuzome a sustainable and environmentally friendly dyeing practice. Step 5 Sewing In the final step, the dyed fabric is sewn into a noren curtain. Skilled artisans carefully match patterns on both sides of the curtain, stitching precisely by hand or machine to avoid any misalignment. In our workshop, each stage of noren production is handled entirely by our experienced artisans, ensuring consistent quality and craftsmanship.

Ulla von Burandenburg × SHOBIEN KYOTO

We are pleased to announce our collaboration on a noren (traditional Japanese curtain) with artist Ulla von Brandenburg, a current resident at Villa Kujoyama, unveiled during an event held at Villa Kujoyama. Ulla von Brandenburg: Ulla von Brandenburg is an internationally renowned contemporary artist from Germany, celebrated for her immersive fabric installations and compelling video works. Her creations offer audiences experiences akin to stepping onto a theatrical stage. Von Brandenburg deeply explores psychology, traditional rituals, and historical memory. Her innovative approach, which bridges contemporary art and performing arts, has been widely acclaimed and exhibited at prominent institutions worldwide, including the Centre Pompidou. Villa Kujoyama: Villa Kujoyama, located in Kyoto's Yamashina Ward, is an artist-in-residence facility managed by the French government. Established in 1992, it hosts artists primarily from France across various disciplines for several months. The artists produce work inspired by Japanese culture and engage actively with the local community. Architecturally harmonizing with the natural environment of Kujoyama, the facility features studios and galleries. Villa Kujoyama is internationally acclaimed as a hub for Franco-Japanese cultural exchange, blending traditional craftsmanship with contemporary art.